U-buig pyppasvorm

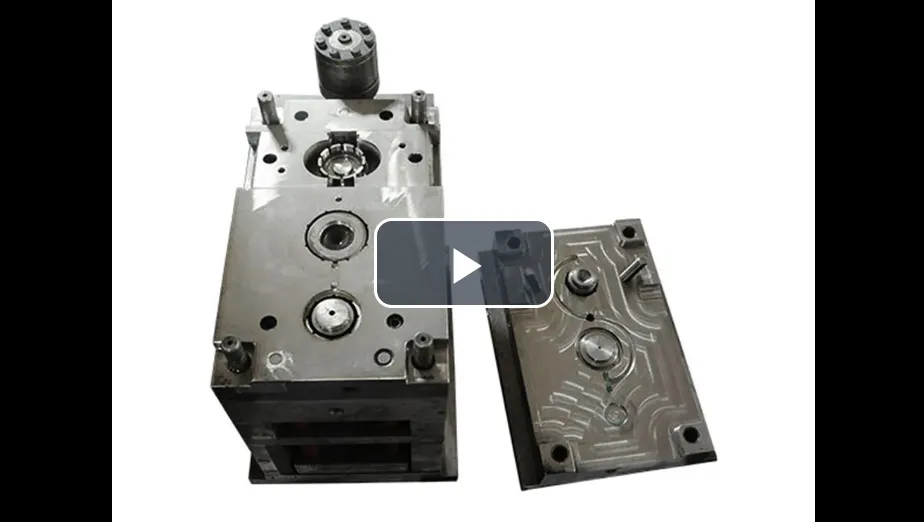

U-Bend Pipe Fitting Mold: Design and Manufacturing Overview A U-bend pipe fitting mold is a specialized tool used in the injection molding or blow molding process to produce U-shaped pipe fittings, which are essential components in plumbing, HVAC systems, and industrial fluid transport applications. These fittings allow for directional changes in piping systems while maintaining smooth fluid flow. The mold's design and precision are critical to ensuring the final product meets dimensional accuracy, structural integrity, and performance requirements. Key Design Considerations 1. Material Selection The mold is typically made from high-grade steel or aluminum to withstand high pressure and temperature during production. Hardened steel is preferred for long production runs due to its durability, while aluminum molds are lighter and cost-effective for prototyping or shorter runs. 2. Core and Cavity Design The mold consists of two primary parts: the core (male) and cavity (female). The cavity forms the outer surface of the U-bend, while the core shapes the inner diameter. Precision machining ensures uniform wall thickness and smooth internal surfaces to minimize flow resistance. 3. Cooling System Efficient cooling channels are integrated into the mold to regulate temperature and reduce cycle times. Proper cooling prevents warping or defects in the final product. 4. Ejection Mechanism After molding, the U-bend must be ejected without damage. Ejector pins or sleeves are strategically placed to release the part smoothly, especially given the fitting’s curved geometry. 5. Venting Air traps during injection can cause voids or burns. Venting channels are added to allow trapped air to escape, ensuring a defect-free surface finish. Manufacturing Process 1. CNC Machining The mold components are precision-machined using CNC milling and EDM (Electrical Discharge Machining) to achieve tight tolerances (typically within ±0.05mm). 2. Surface Treatment Polishing or coating (e.g., chrome plating) enhances wear resistance and improves part release. 3. Testing and Validation Prototype molds are tested with production-grade materials to verify dimensional accuracy, pressure resistance, and flow performance. Adjustments are made as needed. Quality Assurance - Dimensional Checks: Laser scanning or CMM (Coordinate Measuring Machine) ensures compliance with design specs. - Pressure Testing: Fittings are tested under simulated operating conditions to validate durability. - Surface Inspection: Visual and microscopic checks detect flaws like sink marks or flash. Applications U-bend fittings produced from these molds are used in: - Plumbing systems for redirecting water flow. - Chemical processing where corrosion-resistant materials (e.g., PVC, CPVC) are required. - HVAC systems for refrigerant lines or ductwork. Conclusion A well-designed U-bend pipe fitting mold balances precision, durability, and efficiency to produce high-quality fittings. Advances in mold technology, such as conformal cooling and additive manufacturing, continue to optimize production, reducing costs and lead times while maintaining performance standards.

Produkte

kategorie:

-

CPVC T-buispasvorm

Klassifikasie: CPVC pyp pasvormAantal kyke: 511Getal:Vrystellingsdatum: 2025-11-13 17:20:16CPVC T-buispasvormVorm naam:CPVC T-buispasvormHolte: 2 holtesVormgrootte: 50-110 mmVormstaal: Duitsland2316 china2316 of4cr13 vir die holte en kernHek: direkte hekvormstruktuur: hoekpenHardheid van kern/holte: HRC 40-45° graad na vakuum hittebehandelingSpuitgietmasjien: 250-450T Taizhou Huangyan Hong Jin vorm Co., Ltd is in 2002 gestig. Ons is professioneel in die ontwerp en vervaardiging van die pyppasvorm vir meer as 23 jaar.Ons sien uit na lang samewerking met jou.Hier volg die hoofinligting vir u verwysing.Gereelde vrae:1.Wat is jou MOQ?1 stel is OK2.Wat is jou afleweringstyd?Die tyd van... -

PVC U Trap spuitvorm

Klassifikasie: PVC pyp pasvormAantal kyke: 500Getal:Vrystellingsdatum: 2025-11-13 20:30:31PVC U Trap spuitvormVorm naam:PVC U Trap spuitvormHolte: 1 holteVormgrootte: 110mVormstaal: Duitsland2316 china2316 of4cr13 vir die holte en kernHek: direkte hekvormstruktuur: oliesilinderHardheid van kern/holte: HRC 40-45° graad na vakuum hittebehandelingSpuitgietmasjien: 380THier volg die hoofinligting vir u verwysing. Sleutelpunte van PVC-U-buigvormontwerp en -vervaardigingKerntrekmeganisme-ontwerp: Dit is die kerntegnologie van U-buigvorms. Hoe om die geboë kern en syskuifbalk glad uit die produk te verwyder, vereis presiese berekeninge en slim meganismeontwerp (soos hidrouliese silinder...

Nuus

kategorie:

-

[industry news]Dit is belangrik om drie punte in die spuitgietproses te beh...

2024-07-18 18:13:39

Geval

kategorie:

Geen soekresultate nie!

Videos

kategorie:

Aflaaie

kategorie:

Geen soekresultate nie!

Werwing

kategorie:

Geen soekresultate nie!

Aanbevole produkte

Geen soekresultate nie!

Whatsapp

Whatsapp Foon

Foon