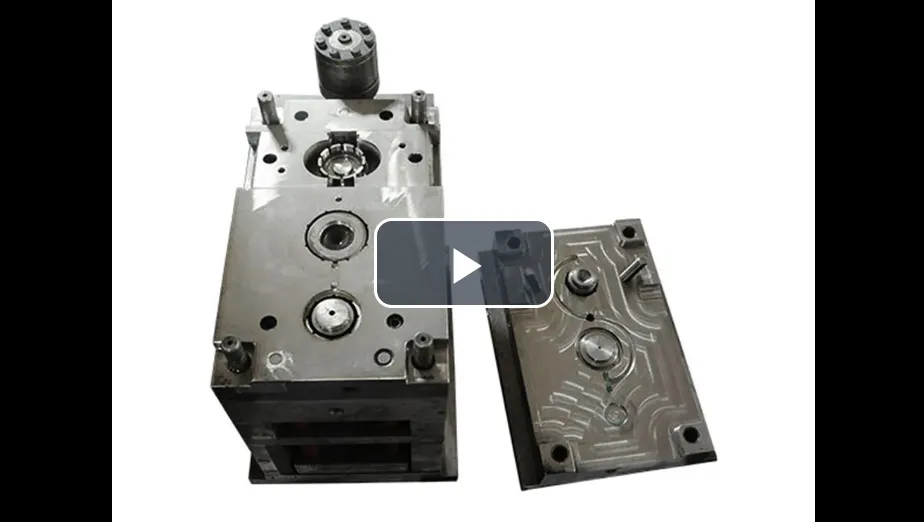

PP-H Three-way Pipe Fitting Mold

PP-H Three-Way Pipe Fitting Mold: Design, Functionality, and Applications The PP-H (Polypropylene Homopolymer) three-way pipe fitting mold is a precision-engineered tool designed for manufacturing high-performance pipe fittings used in industrial and residential piping systems. This mold plays a critical role in producing T-shaped or Y-shaped connectors that enable fluid or gas flow diversion in pipelines. Below is a detailed overview of its design, functionality, and applications. 1. Mold Design and Construction The PP-H three-way pipe fitting mold is typically made from high-grade steel, such as P20, H13, or stainless steel, to ensure durability and resistance to wear. The mold consists of multiple components, including: - Core and Cavity: These define the internal and external geometries of the fitting, ensuring dimensional accuracy. - Cooling System: Integrated channels facilitate efficient cooling to reduce cycle times and prevent warping. - Ejection Mechanism: Ensures smooth removal of the finished part without damage. - Venting System: Prevents air traps that could cause defects in the molded part. The mold is designed for high-pressure injection molding, ensuring consistent production of fittings with tight tolerances and smooth surfaces. 2. Material and Performance PP-H is chosen for its excellent chemical resistance, thermal stability, and mechanical strength, making it ideal for corrosive and high-temperature environments. The mold must accommodate PP-H’s high melting point (160–170°C) and shrinkage rate, requiring precise temperature control during molding. 3. Manufacturing Process The production process involves: - Material Preparation: PP-H pellets are dried to remove moisture. - Injection Molding: Molten PP-H is injected into the mold under high pressure. - Cooling and Ejection: The part solidifies, and ejector pins release it from the mold. - Post-Processing: Flash removal and quality inspections ensure defect-free fittings. 4. Applications PP-H three-way fittings are widely used in: - Chemical Processing: Resistant to acids, alkalis, and solvents. - Water Treatment: Safe for potable water systems. - HVAC and Industrial Piping: Handles high temperatures and pressures. 5. Advantages of the Mold - Precision: Produces leak-proof fittings with consistent quality. - Efficiency: Optimized cooling reduces cycle times. - Longevity: Robust steel construction extends mold life. Conclusion The PP-H three-way pipe fitting mold is a vital tool for producing reliable, high-performance fittings. Its advanced design ensures efficiency, precision, and durability, meeting the demands of modern piping systems across various industries.

Produkte

kategorie:

-

CPVC Male Tee Pipe Fitting Mould

Klassifikasie: CPVC pipe fitting moldAantal kyke: 93Getal:Vrystellingsdatum: 2025-11-13 17:50:05CPVC Male Tee Pipe Fitting MouldMould name: CPVC Male Tee Pipe Fitting MouldCavity: 4 cavitiesMould size:48mm Mould steel:Germany2316 china2316 or4cr13 for the cavity and coreGate :direct gatemould structure:Oil cylinderHardness of core/cavity: HRC 40-45°degree after vaccum heat treatmentInjection moulding machine: 320 T Hongjin mould Co.,Ltd is established in 2002.we have more experience in pipe fitting mould for more than 23years.Cpvc Floor drain mould is used stainless steel for the mould cavity and core .We are looking forward to long cooperation with you.Followi...

Nuus

kategorie:

-

[industry news]The Benefits of Using High-Quality PVC Drainage Pipe Fitting...

2024-08-23 17:33:29

Geval

kategorie:

Videos

kategorie:

Aflaaie

kategorie:

Geen soekresultate nie!

Werwing

kategorie:

Geen soekresultate nie!

Aanbevole produkte

Geen soekresultate nie!

Whatsapp

Whatsapp Foon

Foon